- nothing

Biography

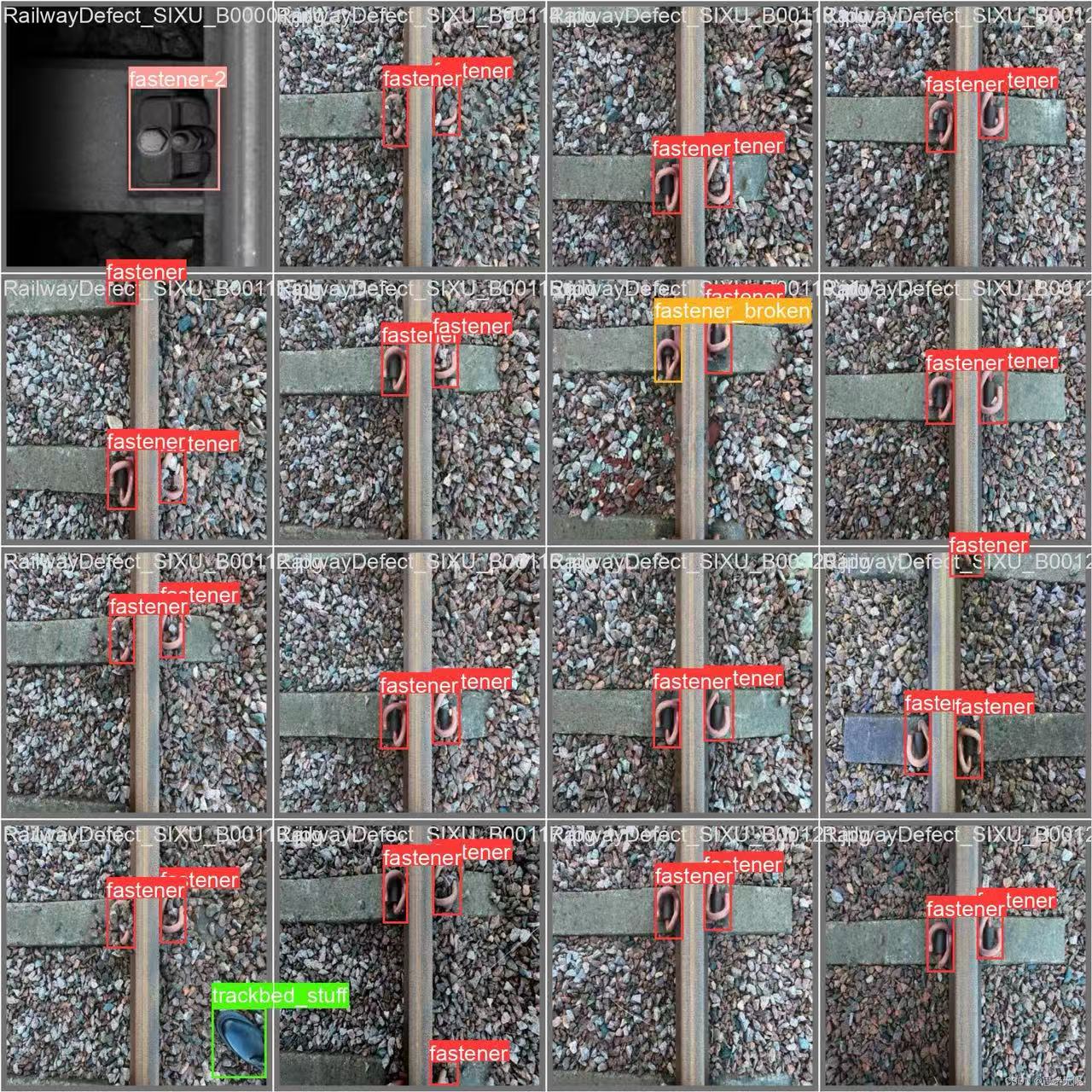

With a solid background in mechatronics and intelligent manufacturing, I have completed systematic studies from associate to master's degree at Suzhou Industrial Park Institute of Vocational Technology, Jiangsu University Jingjiang College, and University of Shanghai for Science and Technology, majoring in mechatronics, vehicle engineering, and business administration. During the Bosch dual-system apprenticeship program, I mastered a wide range of integrated technologies including lathe, milling, grinding, CNC machining, welding, pneumatics, hydraulics, electrical cabinet wiring, Rexroth PLC, EPLAN circuit design, and CAD mechanical drawing, combining theory with hands-on practice. In my career, I actively participated in lean production and Industry 4.0 upgrade projects for automated production lines, driving process optimization, equipment networking, and intelligent scheduling to support enterprise digital transformation. In software development, I contributed to the design and implementation of an enterprise-level management system based on SpringBoot, MySQL, VUE3, and ElementUI, demonstrating strong capabilities in both backend and frontend development. Additionally, I was involved in a computer vision project using Python and YOLOv5 for automated detection of missing parts on production lines, significantly improving inspection efficiency and accuracy. Through diverse learning and practice, I have accumulated rich interdisciplinary project experience and possess strong engineering, teamwork, and innovation skills, committed to continuous growth in the fields of intelligent manufacturing and digitalization.